2016-08-18 16:16:31 hits:1356

How to Avoid cracked pellet when operating the Pellet Machine?

When we use pellet machine to press pellets, sometime it may happen the situation that the pellets are out of shape--the pellets produced are cracked, or even can´t be shaped at all.What causes the pellet machine to press pellets out of shape? How to avoid producing loose pellets?

1.The Characteristic of raw material

The texture of some raw material is relatively soft, which is easy to make pellets. While some is hard or in powder,which is difficult to shape.

Besides, the moisture of raw material is also a main factor of unshaped pellets. The moisture of raw material is better to be kept between 8%-15%. Higher or lower moisture will make it difficult to shape pellets.

Keep good control of crude fiber content of material. Appropriate crude fiber content is beneficial for pellets to bond and will reduce pulverulent ratio, improve pelleting output.

But when crude fiber content exceeds a certain rate, it will affect pellets’ hardness and shaping rate because of low cohesiveness.

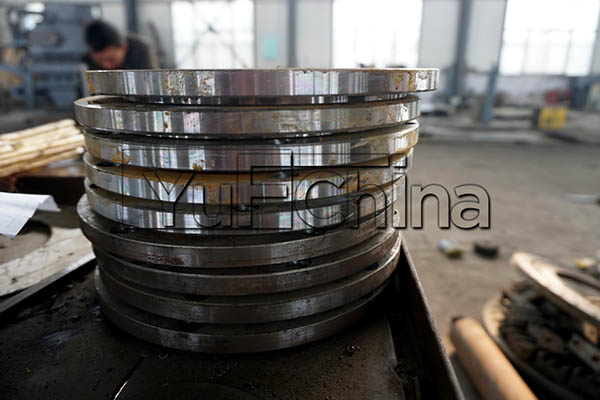

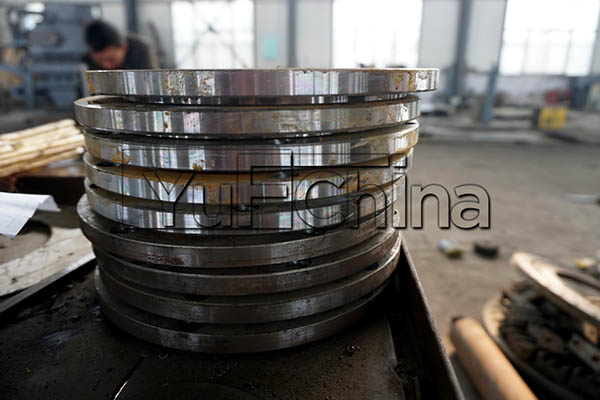

2.The compression ratio of ring die

The compression ratio of ring die means the ratio of effective working length and die holes´diameter. We need to choose suitable compression ratio according to raw material formula and product requirement.

Low compression ratio can increase output and reduce energy consumption, but in that case, the pellets produced are loose with varying length and high pulverulent ratio’╝øon the contrary, pellets would be solid with smooth,glossy surface and low pulverulent ratio, while the cost is high under this circumstances.

3.The gap between press roller and ring die

If the gap between press roller and die is too wide, the pressure is not enough which will cause poor quality of pellet forming. So, clients should strictly follow manufacture’s instruction to adjust gap between press roller and die.

Solutions to avoid producing loose pellets:

Some factors are controllable to avoid unshaped pellets . To ensure shaping rate,output and quality of pellets, we should choose powerful manufacture to guarantee after-sale service. As a user,we can control the raw material used and find suitable machines.