BLOG

| Subscribe to our e-mail can be Downloads Free buyer's guide! |

2015-12-17 11:51:31 hits:663

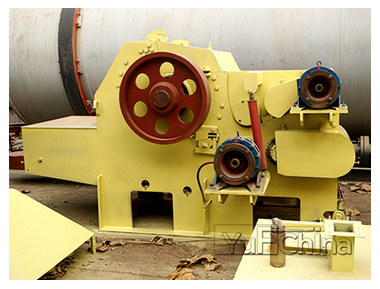

Four points to learn more about multifunctional hammer mill

Features and Scope

Multifunction hammer mill have the features of simple structure, easy operation and maintenance, widely application, low noise. It is the ideal machine for coarse crushing.

It is suitable for pharmaceutical, chemical and food industries, such as material high viscosity, hardness, softness and fiber without restrictions, it can play good crushing effect on a variety of biomass materials.

Working principle

Materials go into crushing chamber through hopper, using a rotary blade and a fixed blade impact, shear, get crushed by the rotating centrifugal force. the material automatically flow at the outlet of grinder, good size materials can be got by replacing different screen.

How to purchase correctly?

If the raw material is cereal-based feed, you can select the top of feed mill; if the raw material is ground grains, such as bread and cereal straw, you can select tangential feed.

The production capacity is larger than the actual production capacity, in order to avoid wear hammer, duct leakage and other causes of decline.

Production decline or fail to meet the design requirements of the phenomenon appeared in the production, the main reasons are:

Ō¢Č Hammer thickness unsuitable or hammer badly worn.

-- Hammer is thinner, the crushing efficiency is higher, but the life span is shorter, so the thickness of the hammer should not be too thin.

-- In addition, the hammer using time is longer, the crushing material is the worse, then leading to reduce grinding efficiency and yields. Hammer should be checked regularly and promptly exchange.

Ō¢Č Improper feeding.

-- Uniform feeding machine requires the consistent flow of material per unit time. Feeding excessive or too small will result in reduced mill output and granularity of quality.

Ō¢Č Hammer layout is unreasonable.

-- Hammer arrangement refers to the number and arrangement mode. Too much or too little hammers can affect productivity.

-- More hammers can improve productivity capacity, but materials will be sandwiched between two sheets, it is not conducive to the discharge from the meshes.

-- Small hammer and screen mesh small, crushing effect is even worse, the dirt materials will be formed on the sieve, the material is difficult to screen out.

PREVIOUS POST

Four strokes teach you how to choose the dryer?