BLOG

| Subscribe to our e-mail can be Downloads Free buyer's guide! |

2015-09-22 14:31:30 hits:649

How to choose a good biomass pellet machine?

1. The stability of the machine

The stability is very important for a machine.For example: if you buy a machine that needs many times maintenance in half a year, even if the machine can produce 20 ton pellets per hour, it is also not good machine.So the stability of the machine is the most important, which can ensure the normal operation.

2. Energy consumption and capacity

-- If only consider capacity, electricity is high, net profit per ton is also little; If only consider saving energy consumption, low electricity, capacity is low, so profits is less each day.

-- So choose the machine will not only consider energy consumption but also consider capacity, you should consider how many pellets can be produced per KW of electricity.

3. The maintenance cost

When many customers selecting a machine, it is easy to overlook the maintenance cost. During pellet machine working process, it needs lubrication, maintenance, debugging, etc. If you choose good design principle, parts precision machine, it can greatly reduce the number and cost on the maintenance, the savings will be transformed into your profits.

4. After- sales service

No matter which brand of pellet machine would never broken. What should we do if the machine is broken? Certainly be maintenance.If the manufacturer enterprise culture is good, after-sales team certainly won't let you down.

5. The investment cost

Many customers only buy expensive not buy right, and consider expensive good, in fact this is not right. Many manufacturers will recommend you to buy their auxiliary facilities, which requires your analysis whether you need these auxiliary equipments or not. In terms of inspection machine, pursuit cost-effective, with minimal investment in exchange for the greatest benefits.

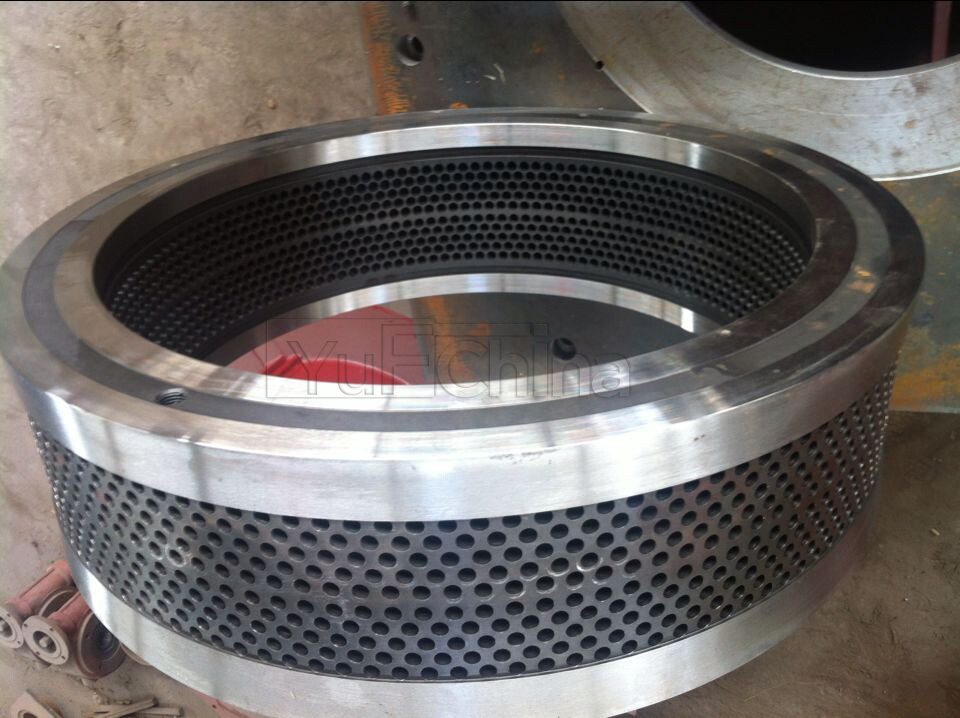

6. Wearing parts

How many kinds of wearing parts? How long life of wearing parts?Some equipment parts are many, such as main shaft, gear, roller eccentric shaft, roller wheel, roller bearing, mold, etc. Some less.These are your cost, dealing with them well will be directly converted into your profits.

7. The simple and easy operation

This is also a need to pay attention to the problem.Your machine is convenient operation, so there is little chance for the problem. So the employees are also willing to do, the level of wages is not high. These are indirect cost savings for you.

PREVIOUS POST

Wood Crusher according to your own needs