2016-03-31 16:31:31 hits:672

How to do routine maintenance for biomass pellet machine?

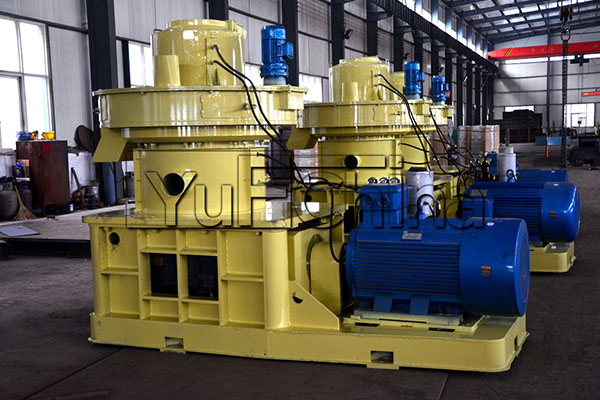

Biomass pellet machine is the key equipment of biomass energy industry, it can effectively improve production efficiency. However, many customers neglect the maintenance during the production, thus reduced the lifetime of the machine. Then, during normal operation, how should we do maintenance for the biomass pellet machine?

1ŃĆüHeat dissipation and cooling

Biomass pellet machine’s roller presses the wood sawdust into the mold hole, the raw materials push subsequently until the pellet is formed. This mode of operation will cause the machine to high temperatures, so the timely oil supply and heat dissipation can effectively extend the working life of the pressure roller, increasing valid output of the biomass pellet machine roller.

2ŃĆüMaterial moisture content

If the raw material moisture content is too high, there will be blocking phenomenon raised. Therefore, before production, users must test the moisture content. If the water is too high, dry them first. Avoid damp material increases the load of the machinery, and impact the normal operation.

3ŃĆüRegularly lubrication check

During use, pay special attention to check the transmission parts of the biomass particles machine, ie the drive gear. Regularly check the lubrication, properly add lubrication and grease, to make sure the gear is good, and the biomass pellet machine runs more stable and reliable.

4ŃĆüRegular inspection and replacement of parts

Periodically inspect all the bolts, screw, and blade whether loosening, especially coupled screw between the drive wheel and die; always check whether any leakage, and timely replace the seals. After using for a long time, replace the wearing parts and broken parts, to ensure the normal operation of the machine.

5ŃĆüCleaning

After stop the machine, rotating drum should be removed for cleaning, and then installed for the next use. If a long time off, user must clean the whole machine body, coat the surface with anti-rust oil, cover the machine with tarpaulin.

In addition, biomass pellet machine should be put on a clean dry indoor place, it shall not contain acids and other corrosive gases.