BLOG

| Subscribe to our e-mail can be Downloads Free buyer's guide! |

2015-09-16 11:18:30 hits:898

Using pellet mill, need raw material firstly be crushed?

The complete pellet making production line, in addition to main force- pellet machine, Crusher, mixer and subsequent cooling and packaging equipment, is also the main common equipment in the whole production line.

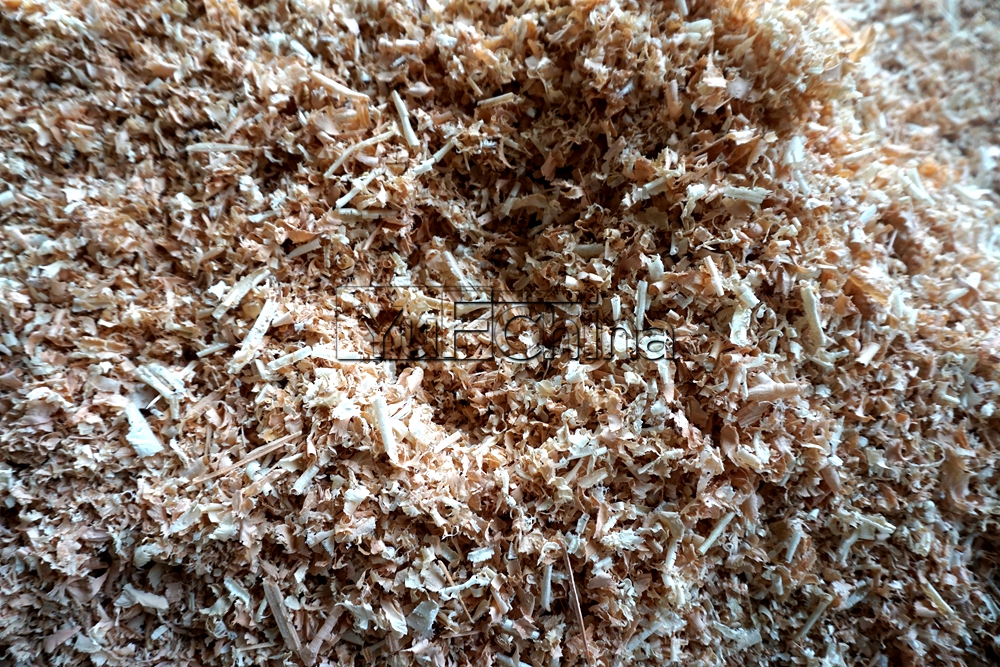

For raw materials, it is better to crush before pellet making.

Ō¢Č The crushing of raw material is one of the important working procedure in process of pellet fuel production.

Ō¢Č The main purpose of crushing is to increase raw material exposure surface area with improving the combustion efficiency, make some of raw material easy to handle and transport, improve mixing performance of the material,improve the efficiency of granulating , and improve the pellets’ quality.

Ō¢Č It not only directly affect the cost of pellet processing (power consumption, vulnerable parts), but also influence the material mixing and the quality of granulating.

The influence of material features for granulating

Ō¢Č All kinds of raw material’s physical properties, combustion performance, hardness, density, moisture content, and organization structure have differences.

Ō¢Č Raw material size after crushing and the pellet quality after crushing material is one important factor of affecting the molding fuel product quality indicators (such as resistance to fall, the density of water permeability resistance and relaxation, etc.).

Ō¢Č If raw material of natural density and combustion performance is very high, it will have a higher capacity of pellet production and a higher quality of pellets.

Pellets shaping requirements for raw material grinding size

Ō¢Č For some certain principle of pellet machine forming pellets and some certain methods of pellets forming, raw material grinding size should be smaller than pellet size.

Ō¢Č If raw material size is uneven, especially morphological differences, molding surfaces will appear cracking phenomenon, the strength of the product will be reduced, affecting pellets’ performance and transport properties.

Ō¢Č If raw material is very long and the effect of crushing is poor quality, it will directly affect the forming pellets’ effect, the production efficiency and power consumption.

Normally, raw material size is smaller, elongation of the particle is bigger, easy to compression, raw material easy to shape; At the same time, small particle size, the particles’ packing characteristics in the compression process, flow characteristics and compression features will be significant influence for biomass forming.

Big size of raw material, low packing characteristics degree between particles, touching each other is not compact, more difficult to compression, not easily to shape; The bigger size of raw material, original phase structure is not easy to be destroyed under low pressure, cohesion between molecules cannot be increased, caused particles combined loosely, resulting in a decline quality of the product.

The negative influence of raw materials without crushing

During practical production, such as straw raw material,not easy to smash, often have a long raw materials mixed with feeding room, caused wrapping material, blocking device, not continuous forming, shorten the effective production time, heat not be spread in a timely manner, appear "spout hot air" phenomenon, not only energy consumption increasing, the release of spark still can cause fire.

PREVIOUS POST

Three Advantages of Palm Shell Biomass Pellets